De Bouwvak komt eraan! Lees meer over onze openingstijden

Direct technische ondersteuning nodig?: Lees meer

Direct technische ondersteuning nodig?: Lees meer

Glass supports walls – the intelligent building stiffener.

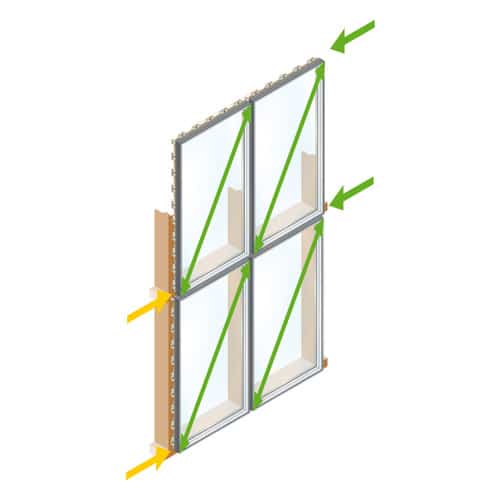

| A research project together with Wood Research Austria led to the development of a support system with a multi-part load-bearing exterior wall construction made of glass and wood. For the first time, CLIMA+WOOD makes available a ready-to-install glass-wood system. |  |

Glass fulfils the basic necessity for urban people, to connect them with nature and to provide a safe and comfortable atmosphere. Natural daylight and protection from rain and wind alone, no longer suffice for modern requirements. Energy savings and reduction in greenhouse gases are important factors. All of this is possible with the latest development in glass technology – as proven by current studies at the Danube Universty in Krems. Large areas of glass are even energy winners in the North, and reduce the heating requirement in comparison to a passive solid wall by U = 0,12 W/m².K. Architecture and its intelligent technical transformation shape the ambience, slim buildings and reduced supporting elements underline the aesthetic of modern design.

CLIMA+WOOD the new system solution for multi-section glass-wood constructions for building stiffening which combines transparency, stability, energy gains and weather protection. A significant advantage of this wall element is that CLIMA+WOOD contributes to the stability of the building against wind pressure and suction. This means that other structural construction parts such as wind bracing or wall areas can be considerably reduced or even eliminated all together. CLIMA+WOOD elements are capable of withstanding loads in the plane of the glass. The glass is therefore also a load-bearing and stiffening element.

| download | CLIMA+wood as element of the primary support system - a live example |

| 1 - multi-laminate bonded polywood frame 2 - Norton tape 3,2mm x 6mm 3 - 32-component supporting silcone bond 4 - insulating glass: double or tripled glazed 5 - screws zinc-plated |  | ready to install CLIMA+wood element |

CLIMA+WOOD is suitable for

- single family homes as well as semi-detached and terraced houses

- wintergardens

- additions and extensions with max. 2 storeys and 7m eaves height

The residential „Schattenbox“ in the Vienna forest was awarded the Lower Austria wood building prize for 2009. Within the scope of the research project for Superreal – Superlab / Dold and Hasenauer OG, ECKELT supplied triple glazed insulating units with mechanical restraints including SSG bonding to patented coupling plate.

|  |

| NO wood building prize 2009 shadowbox in the Vienna forest Superreal - Superlab | Dold und Hasenauer OG |

Photo-realistic appearances on glass provide new design possibilities.

a| colour space and print resolution:

|  |

CMYK | design |

b| dimensions:

c| glass types

Please consult us for suitable glass types as substrates for digital printing.

Of particular recommendation is the „de-materialised“

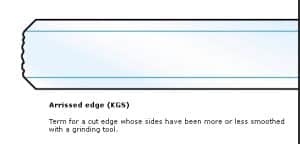

a| edge working

| Standard edge working for digitally printed glass is arrissed. Orders requiring ground edges (KGN) or polished edges (KPO) will have the corners of rectangular units matt flattened. |  |

b| drilled holes

Production technical minimum edge distances are to be taken into account.

| edge working | |

| production-technical minumum distances SafePerform tempered glass |

The suitable glass substrates may typically be printed on surface #1 (viewing side) or surface #2 (rear side). This means that you can play specifically with reflecting or matt aesthetics.

Characteristic for the appearance of the standard version of digital glass printing is the translucency of the colours. This allows the background to be brought into play, depending on the angle of viewing and lighting conditions. An ideal solution for interior room design, such as doors and partitions, which are normally viewed from both sides under similar lighting conditions.

At higher light intensities in the background, e.g. viewing against daylight, the standard colours may look too pale. In such situations we recommend using the „backlit“version. In comparison to the standard colours, these have less light transmittance, are printed heavier and therefore more colour intensive. A solution for externally-oriented applications in insulating units and interior space design e.g. infra-red or sauna cabins with different light intensities which are viewed from both sides.

For single-sided views of images or logos we recommend a back-covering of the whole surface or only the printed image. The colour rendition is thereby more brilliant. When backlit by daylight or artificial light, the white background also acts as a diffusor. If lamps are very close behind the glass it is possible to use an „intensive white“ back covering to achieve a very uniform distribution of light.

Digital glass printing can typically be executed on normal substrate. The multitude of application possibilities will normally require some kind of safety glass to protect from injury or falling. We therefore recommend using SafePerform, fully tempered safety glass or ProtectPerform, laminated safety glass. With backlit applications or these in insulating units, it is probable that a greater load will be applied to the glass. These applications require a higher resistance to temperature change which necessitates the use of fully tempered SafePerform.

When transporting, handling and installing it is important that no adhesive tapes, self-adhesive distance pieces or other strong-marking materials are put into contact with the printed surface. Storage of the glass in the open is to be avoided and we recommend that the glass is kept from being soiled until the glass is installed. This particularly relates to concrete, paint or weld-splatter.

Installation of digitally printed glass should be carried out – as per conventional glass – in frames with dry gaskets or frameless using fittings. Should wet-glazing with silicone (neutral curing) or stuck onto walls, we recommend that this is only carried out on the non-printed side of the glass. If direct contact between the printed surface and silicone or other sucdigitally printed glass. Until successful tests have been carried out by us, we recommend against use in such applications.

In addition to our general cleaning guidelines, the following points for the printed surface are to be observed: For typical regular cleaning using the wet method, we recommend lots of clean water at a maximum temperature of 50 degrees Celsius and using a household mild cleaning agent (e.g. liquid dish soap) without scouring agents. Mild glass cleaners can also be used. Regardless of the cleaning method used (wet or dry, water, soap suds or glass cleaner) only soft cloths are to be used. If sufficient liquid is used then it is also possible to use soft sponges or rubber squeegees. Unsuitable and prohibited are scouring or abrasive cleaning agents and cloths, or sharp, scratching metals tools such as blades, scrapers of knives.

| Please download here our general cleaning recommendations |

a| quality

SafePerform tempered glass is subject to a continuous self and independent certification.

| technical data SafePerform tempered glass |

b| marking

Digitally printed glass on untreated float glass or laminated safety glass of float glass is not marked as standard.

Should safety glass be used, then these are marked as standard as Tempered Safety Glass (ESG or ESG-H).

Please note! Should marking other than the standars be reuiqured, it is imperatie that this is given in writing at the time of the order.

| standard marking and location tempered glass | |

| standard marking and location tempered and heatsoaked glass |

c| certification

Harmonisation certification Fully Tempered–HST (ESG-H) fulfils the requirements of the German Building regulations A Part 1 2004/1 Appendix 11.4.2

vandaglas eckelt possesses all certification for such requirements in accordance with 89/106/EEC of the Council of the European Community. The applicable CE harmonization statements can be downloaded below.

| certificate of conformity ESG-H | |

| CE conformity certification |

Since the quality of the print is dependent on the original picture and the type of data sent by the customer, we use the customers data 1:1 without corrections for our high-resolution prints. Picture quality should not be below 72 dpi, image enlargement should be avoided.

Data formats: .tif, .ai, .psd

Particulars:

Data transfer: via ftp upload – ftp.eckelt.at

To receive a password for your data transfer please contact your representative.

| Please download here our guidelines for data transfer for orders. |

our consultants

| E name.surname@vandaglas.de M xx xx xx xxx | E name.surname@vandaglas.de M xx xx xx xxx |

| Curved Glass

vandaglas GmbH – Standort Berlin

Am Zeppelinpark 24

D-13591 Berlin, Germany

T +49 (0)30 35 19 67-0

F +49 (0)30 35 19 67-66

E doering@vandaglas.de

| XL Glass & Facade Systems

vandaglas ECKELT GmbH

Resthofstraße 18

A -4400 Steyr, Austria

T +43 (0)7252 894 0

F +43 (0)7252 894 24

E eckelt@vandaglas.at