De Bouwvak komt eraan! Lees meer over onze openingstijden

Direct technische ondersteuning nodig?: Lees meer

Direct technische ondersteuning nodig?: Lees meer

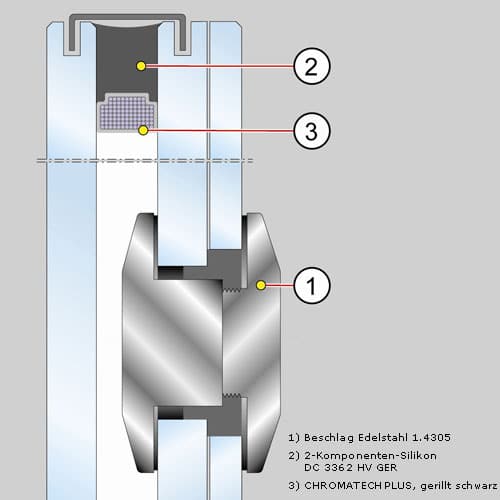

LITE-WALL ISO is a point-fixed performance unit of glass, structural bond and fitting.

| It offers a point-fixed insulated glass with optimum system separation between safe mechanical restraints of the laminated inner sheet without penetrating to the outer sheet which achieves improved thermal insulation. Wind loads as well as self-weight of the outer sheet are carried by the silicone structural bonding to the inner sheet. In addition the outer sheet of fully tempered afety glass is connected to the inner sheet with four mechanical restraints. |

The patented glass fixing characterises its complete surface without any penetration to the outer sheet. LITE-WALL ISO uses a minimum number of visible connections for maximum transparency in facades, roofs or entrances. The number of fittings depends on the project-specific sizes and load conditions. The fittings are grade 1.4305 stainless steel and are factory pre-fitted and sealed. In connection with filigree structures it is possible to create aesthetic glass walls which generously fill interiors with daylight and which harmonise with existing building materials. |  |

LITE-WALL ISO fulfills the requirements of ETAG 002 - „Guidelines of the European technical Approval for structural sealant glazing “ - and can be classified as Type III according to Point 2.1. of this guideline – with restraints to minimize danger should the bond fail.

The integrated lite-wall restraints provide mechanical restraint in the case of structural sealant failure up to the point of static overload. The laminated safety glass inner sheet remains anchored to the sub-frame by the fittings.

Wind loads as well as self-weight of the outer sheet are carried by the silicone structural bonding to the inner sheet.

The positive experience from more than 10 years in service supports the high product safety aspects.

| Maximum production size | : 2500mm x 5000mm |

| Minimum production size | : 250mm x 450mm |

| Maximum aspect ratio | : 1:20 |

In any case it is necessary to carry out a project-specific structural analysis.

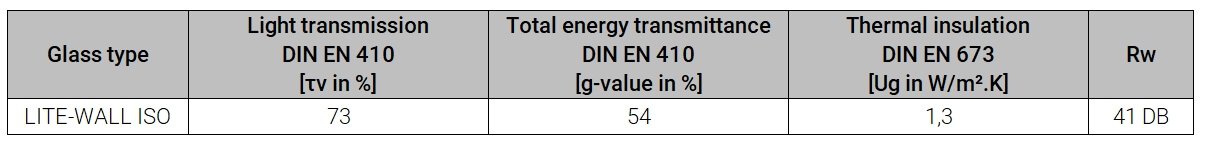

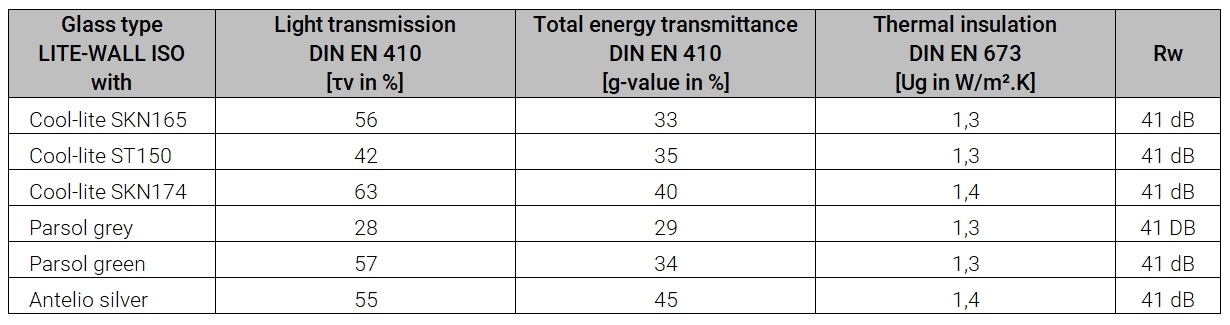

The values are calculated in accordance with the standards DIN EN 410 (for light and energy factors) and DIN EN 673 (for the thermal factors). The values can not only be used for assurance of product characteristics.

The tolerance is ± 3 %-points for light and energy factors and + 0,1 W/m².K for thermal conductivity.

The construction principle – fixing the fitting only to the inner sheet – results in a technically optimum thermal performance even where the fittings are located. At normal temperatures there is typically no condensation build-up on the roomside of the fittings.

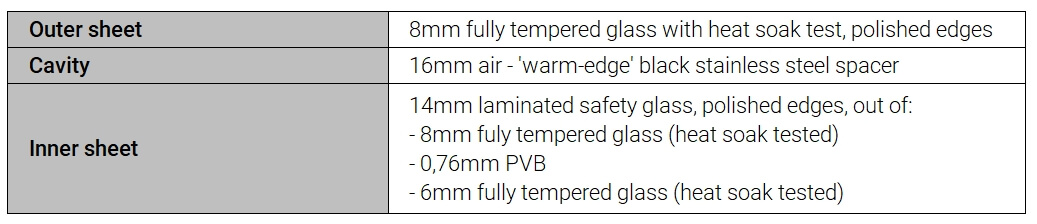

Warm edge solution using CHROMATECH PLUS ψ 0,115 W/m.K spacer bars as standard.

A „warm-edge“ system reduces the warm bridges at the edges which improves the facade U-Value UW and also reduces condensation at the edge of the insulated unit.

|  |

visually attrachtive surface appearance of a typical warm-edge spacer | isotherm comparison lite-wall iso |

A correct choice of glass type can fulfill the most challenging design requirements. Apart from the standard composition of the basic floatglass, the permit also allows the following glass types to be used for lite-wall iso:

|  |

The recently developed ECKELT Spider fittings fulfill the technical requirements of fixed and moving supports. The patented inserts allow better accommodation of tolerances and when used correctly ensure the functions of fixed support, horizontal sliding support and moving support.

|  |  |  |

Structural analyses of the connection fittings are not the responsibility of vandaglas ECKELT.

Material data sheets are available upon request. Exact technical information for applications is only available in pdf files. DWG- and DXF-files are only shown as drawings. For the files please click on one of the icons below.

|  |  |  |  |  | |||||

spider | angle | series 5000 | articulated connection | system fittings | fins+beams |

| - Fixed and moving support arrangement lite-wall iso |

With respect to the use of lite -wall iso as a building product, the Austrian Institute for Building technology (OIB) has recognized it in the material list ÖE under point 3. Building products of Glass in ETAG 002 for bonded glass constructions.

Based on completed component testing we have established and verified calculation programs together with CDI Saint-Gobain. This basis has been integrated into the SJ MEPLA Version 2.5.0 [Website??] calculation program and can be used for initial structural analysis.

Maximum deflection:

always measured against the main support

direction facade l/100, roof l/200

The dimensioning of the seal depth for dynamic loading is carried out in accordance with ETAG 002 point A.2.3.1. The static long-term load is carried out in accordance with point A.2.4.1.

| - General glazing guidelines |

1. The sub-frame must be capable of supporting the self-weight of the glass elements, wind loads and the resulting loads.

2. The deflection of the sub-frame when the above mentioned loads are applied must not exceed 1/300 of the facade height.

3. Stabilisation of the sub-frame by means of the glass is not allowed.

4. The connection of the glass units to the sub-frame is to follow the fixed- / moving connection principle.

For the inner seal there are pre-formed silicone profiles available. The outer seal (weather-seal) must be carried out using suitable sealing material which is compatible with the secondary seal – DC–3362 HVGER – of the insulating unit. DOW Corning DC 791 is a compatible silicone sealant. The stainless-steel restraining clips in the edge of the glass must be cleaned prior to sealing the joint. The instructions of the sealant manufacturer are to be strictly followed.

Installation is only to be carried out by professional glaziers who have been trained by vandaglas eckelt for this kind of work.

Important installation notes can be downloaded here on the right of the page.

| - Design notes joints and corner details, interfaces lite-wall iso | ||

| - Installation notes lite-wall iso | ||

| - General cleaning instructions |

lite-wall mono is marked as standard in accordance with the permit.

| - standard marking and location lite-wall mono | |

Harmonisation certification lite-wall mono fulfills the general construction permit in Germany Z-70.2-19 DIBt.

| - Harmonisation certificate lite-wall mono (german version) | ||

| - Harmonisation certification |

| Curved Glass

vandaglas GmbH – Standort Berlin

Am Zeppelinpark 24

D-13591 Berlin, Germany

T +49 (0)30 35 19 67-0

F +49 (0)30 35 19 67-66

E doering@vandaglas.de

| XL Glass & Facade Systems

vandaglas ECKELT GmbH

Resthofstraße 18

A -4400 Steyr, Austria

T +43 (0)7252 894 0

F +43 (0)7252 894 24

E eckelt@vandaglas.at